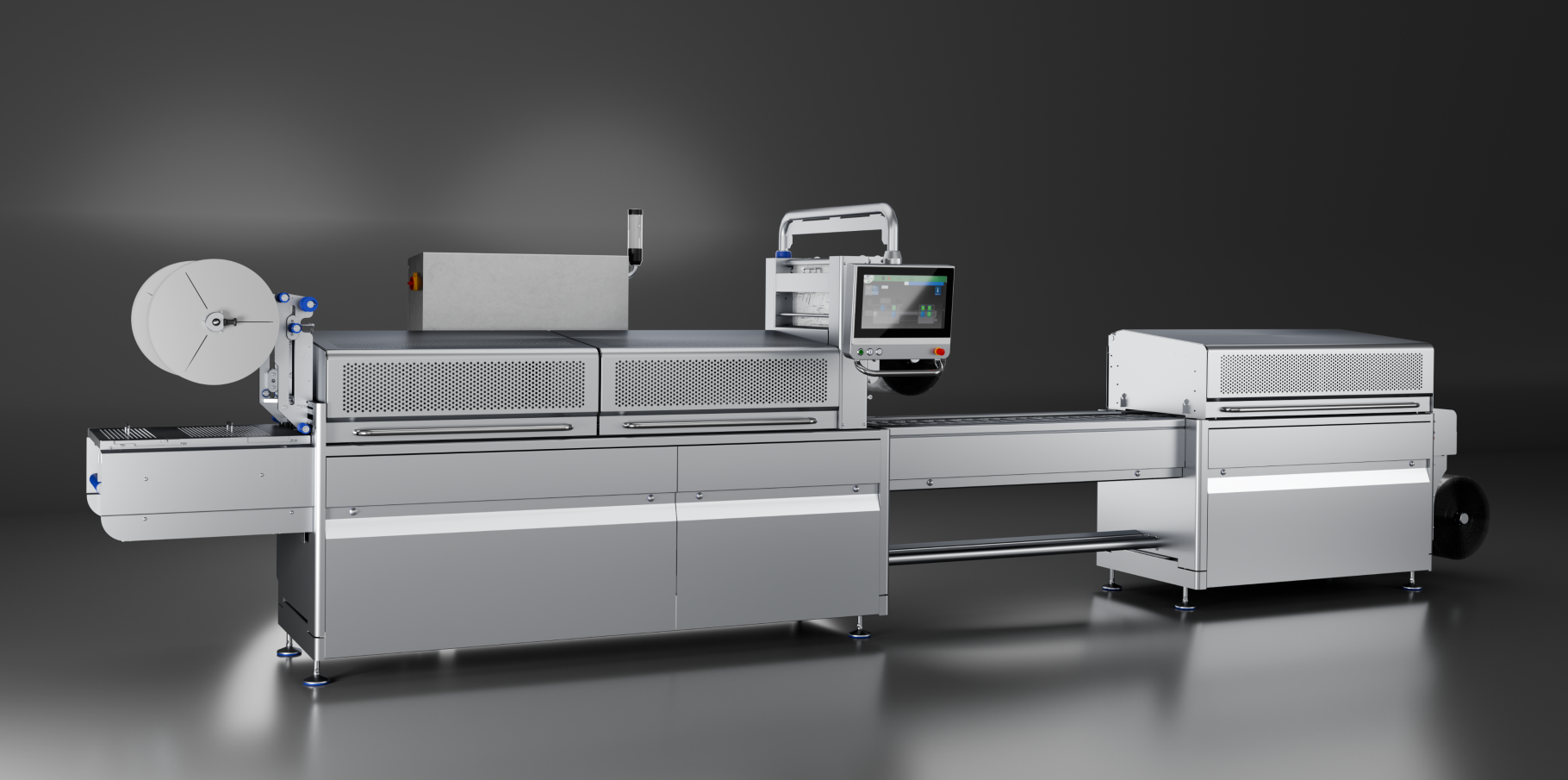

Mecapack thermoforming machine

Creation and design of the new cladding for the FS950 thermoforming machine. Made in France by Mecapack, 2024.

Challenges

Mecapack is a major French manufacturer of food packaging. Their design office wanted to significantly improve the perceived value of use and esteem of their thermoforming machine, particularly in terms of hygiene and cleanability issues.

Recognized for the reliability and durability of their technology, Mecapack wanted to highlight the general quality of their thermoforming machine and its robustness in the face of high-intensity cleaning and maintenance tests.

Solutions

The machine now has large flat surfaces, structured with slight flow angles to integrate the technical hooks and eliminate all the retention spaces for dust, water, and other food likely to be trapped.

We worked on simplifying the chassis and optimizing the various workstations (maintenance cabinets, loading bridge, protective casings, columns, etc.) with a view to aesthetic consistency and specificity of use for each element.

We have developed specific openings, cutouts, and handles, and a complete redesign of the new control screen.

The design study is a listening and analysis of the issues surrounding the machine, its structure, and its uses by the different stakeholders.

Let's get in touch!

Studioboost - bureau 6 • 28 boulevard Benoni Goullin44200 Nantes - France // +33 (0)6 50 72 27 20

studio@studioboost.fr

Armchair

fr

fr